Smart-E-Factory – energetically and ressource efficient production

According to the Federal Environment Agency, the industrial sector accounted for 29% (equivalent to 699 TWh) of Germany’s final energy consumption in 2021 and has great potential in terms of electrical energy savings.

In order to realize solutions on an industrial scale for these challenges, a consortium in the Smart-E-Factory project funded by the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV) and led by Fraunhofer IOSB-INA at the Innovation Campus Lemgo is working on solutions for an energetically optimized factory.

News & Events

News & Events

News & Events

Project Description

Industrial production holds great potential for saving electrical energy and thus for achieving global climate targets. Processes such as lowering and lifting loads in high racks, transporting materials and goods, and thermal processes in production facilities cause load peaks and high energy consumption in factories. Similarly, potential savings are associated with possible material savings through improved planning and production processes. However, while in one place an oversupply of renewable energy is generated, in another place peak loads in production have to be covered by the transmission grid due to a lack of optimization.

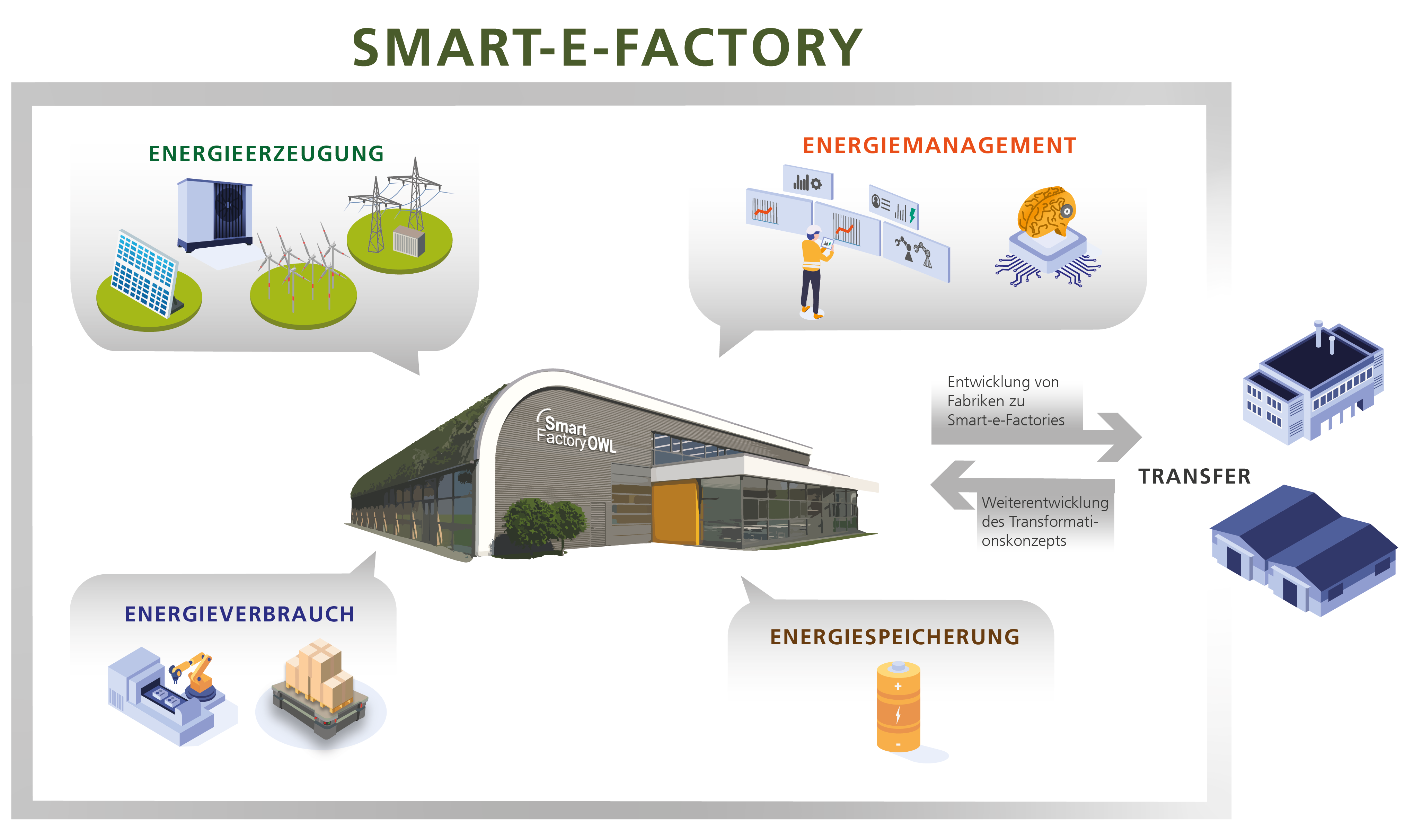

Digital solutions are needed to address these technological challenges and to support industry in implementing climate-friendly technologies. To this end, a consortium of research and industry partners from East Westphalia-Lippe has formed and is developing a model factory based on the example of Lemgo SmartFactoryOWL: the development of a Smart-E-Factory. The BMUV is funding the project over the next three years and the research and development of digital technologies for the energy optimization of factories that this will enable, as well as the transfer of these to small and medium-sized enterprises.

Fraunhofer IOSB-INA from Lemgo is leading the project consortium. Also involved are the Institute for Energy Technology (IFE) of the Ostwestfalen-Lippe University of Applied Sciences (THOWL), the software company IANUS Simulation GmbH and the operator of CUNA Produktion, which is located in SmartFactoryOWL, Hadi-Plast GmbH. In addition, several associated partners such as Stadtwerke Lemgo, Weidmüller, Lenze and Effizienz-Agentur NRW are supporting the project.

The plan is to gradually develop and deploy fundamental technologies from the field of artificial intelligence (AI) for the optimization of industrial plants in combination with regenerative energy generation as part of holistic intelligent energy management. The project consortium is developing transferable solution modules to reduce CO2 emissions in industry. Here, the project focuses on mechanical motion sequences in an industrial manufacturing facility and the associated energy consumption as well as AI-based optimization approaches to reduce emissions. The Smart-E-Factory defines itself as a resource-saving production and, to this end, aggregates information and data from the areas of energy generation,

-management, consumption and storage into a transparent, holistic, real-time picture of the situation

Success stories

Supporter and consortium

The Smart-E-Factory project is one of the AI lighthouses for the environment, climate, nature and resources funded by the BMUV with the aim of transferring the developed technologies to industry as widely as possible. Many technological solution approaches are currently still too slow to find their way into industry. There are various reasons for this: In addition to the lack of maturity of R&D results, many small and medium-sized companies lack the necessary decision-making and action expertise on possible energy-saving potential in their own companies as well as technical possibilities. In addition, there are uncertainties about the investment effort with unclear ROI. For this reason, the project consortium places a strong focus on transfer through practical solution approaches. To this end, the project partners will create offerings in the SmartFactoryOWL to be open to interested parties and provide access to the technologies at any time via LabTours, events and implementation projects.

Fraunhofer IOSB-INA Lemgo: Fraunhofer IOSB-INA (www.fraunhofer-lemgo.de) in Lemgo was founded in October 2009 as the industrial automation site of the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation (IOSB). The Lemgo site, which currently has about 100 employees, focuses on systems engineering for intelligent automation systems in the fields of Intelligent Sensor Technology, Industrial Communication, Cybersecurity, Big Data, Machine Intelligence and Human-Machine Interaction. On this basis, we can efficiently support people in making informed decisions, optimizing processes and intelligently controlling technical systems. With SmartFactoryOWL and Lemgo Digital, Fraunhofer IOSB-INA operates two outstanding real laboratories for the digital transformation of industry and municipalities.

Fraunhofer IOSB-INA, Campusallee 1, 32657 Lemgo Contact: Nissrin Arbesun Perez, M.A. Tel: 05261 942 90 93 E-mail: nissrin.perez@iosb-ina.fraunhofer.de www.iosb-ina.fraunhofer.de

The Institute for Energy Research (iFE – https://www.ife-owl.de) is an interdisciplinary research institute at the Ostwestfalen-Lippe University of Applied Sciences. The researchers involved combine expertise from the fields of electrical engineering, mechatronics, thermodynamics, fluid dynamics, process engineering, building physics and economics. The institute’s research areas include research into the “production of the future”, i.e. the optimization of industrial production processes in terms of energy efficiency and sustainability as well as quality and flexibility.

Contact: Prof. Dr.-Ing Thomas Schulte, Institute for Energy Research, Ostwestfalen-Lippe University of Applied Sciences, Campusallee 12, 32657 Lemgo, Tel: 05261 702 5828, E-Mail: thomas.schulte@th-owl.de.

Hadi-Plast GmbH & Co. KG Kunststoff-Verarbeitung: Hadi-Plast specializes in the certified production of technical precision injection-molded components made of thermoplastics. Hadi-Plast GmbH & Co. KG Kunststoff-Verarbeitung, Zieglerstrasse 9, 33161 Hövelhof, Germany, Contact: Dr. Karsten Anger, Tel.: 05257 97790, E-Mail: info@hadi-plast.de, www.hadi-plast.de

IANUS Simulation: For more than 12 years IANUS stands for experience and competence in the field of 3D CFD flow simulation in the plastics world. In addition to simulations for the plastics industry, the optimization of machines for the pharmaceutical and food industries, as well as the design of chemical reactors, furnaces or heat exchangers and the simulation of air and wind flows are among the core competencies. The two business areas consist of pure services and individual software solutions, which are developed by an interdisciplinary team of experienced engineers, mathematicians, physicists and computer scientists.

IANUS Simulation GmbH, Meisenstraße 96, D-33607 Bielefeld, Germany

Partners

Fraunhofer IOSB-INA

AI Technologies

OWL University

Energy and DC Technologies

Hadi-Plast

Operator of CUNA Production

IANUS Simulation

Simulation of Energy Flows

Ministry

Supporter of Project

Weidmüller

Associated Partner for Energy Management Systems

Lenze

Associated Partner fpr DC Technologies

Stadtwerke Lemgo

Energiegenerator

Effizienzagentur NRW

Transfer of Know How

Z-U-G

Project Supporter

Application

The KI Reallabor also supports you in integrating these results into your company.

Funded by: