The production at SmartFactoryOWL

The production at SmartFactoryOWL

PRODUCTION

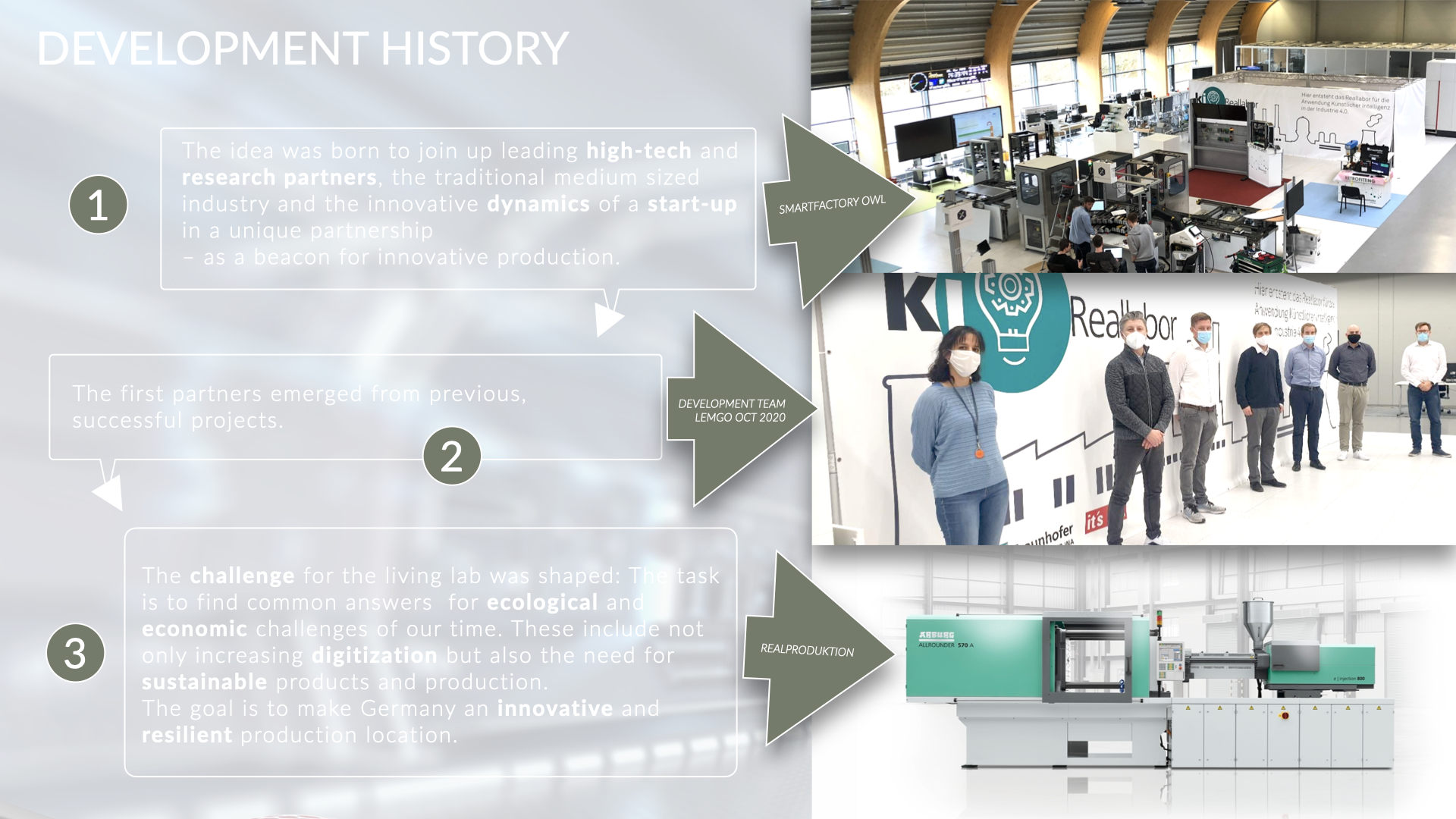

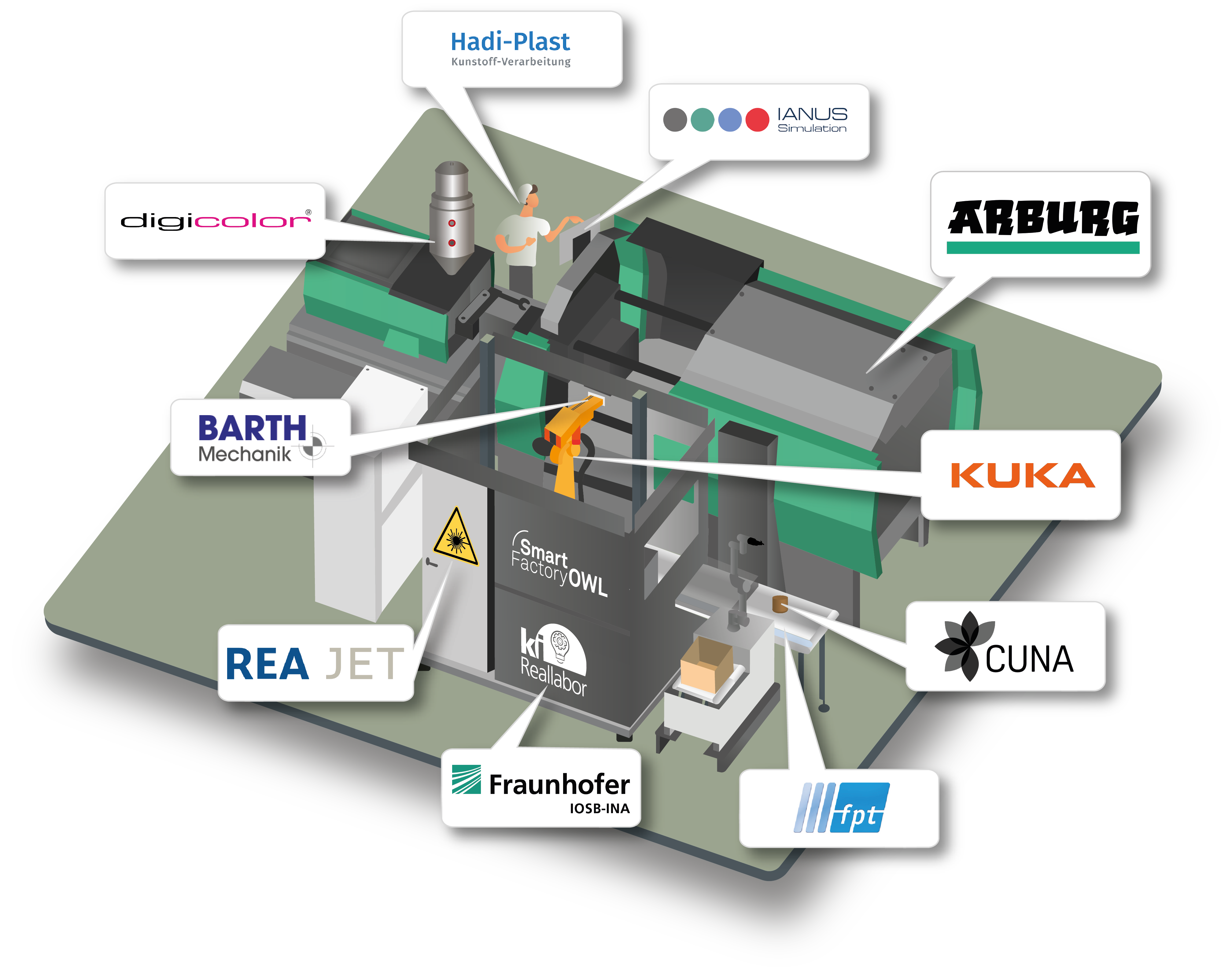

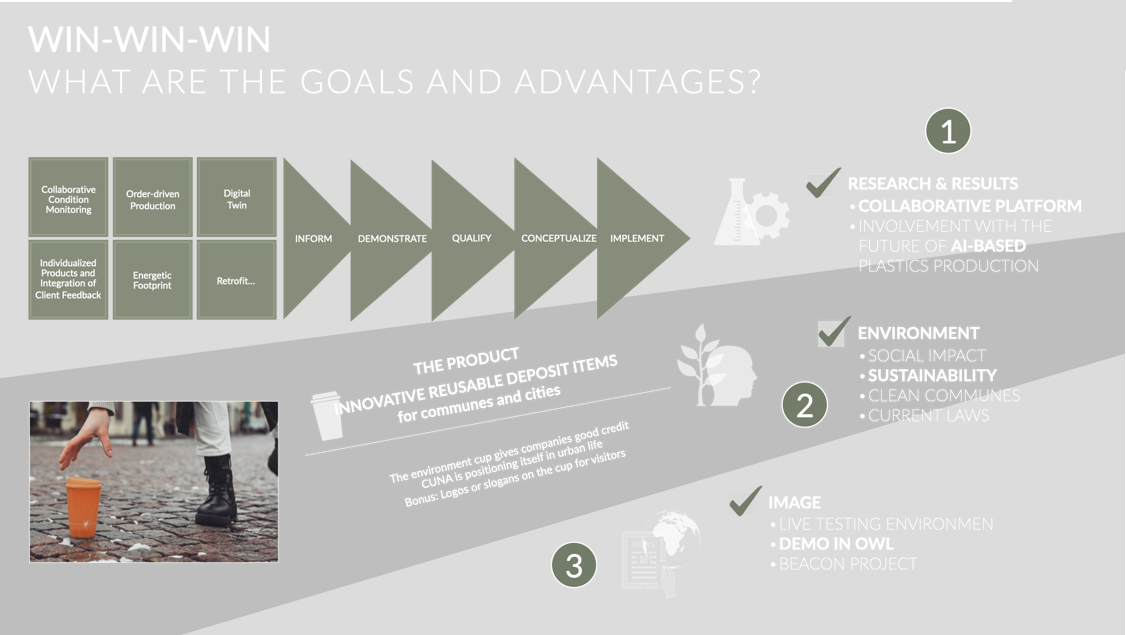

How does the sustainable production of tomorrow works? The fact that technical innovation and environmental protection can harmonize is demonstrated by the cooperative of 10 partners in SmartFactoyOWL, who jointly produce products under the CUNA brand.

CUNA Products GmbH produces reusable cups from CO2-neutral, plant-based material. CUNA, founded in 2018, is characterized by a unique, sustainable concept with a future-proof product idea: the cups are made from a bio-based plastic that dispenses with oil, feature high quality and are reusable as well as recyclable. The special feature: not only is the material used for production made from renewable raw materials sustainable, but also the recycling cycle specially organized by CUNA. For this purpose, a material cycle is created via the return flow of used cups of the pool system, because the ecological reusable cups with the distinctive CUNA flower symbol are mainly used in the deposit system in the catering industry or at festivals.

But that is only the ecological part of the project. In addition, the partners are also bringing to this plastics production the smartness that we have been demonstrating in our factory for some time – and showing what the networked plastics production of tomorrow will look like. The setup of highly modular and automated production is already characterized by a high level of technology use. This will be enriched by networking, artificial intelligence and agile research transfer. In the future, customers will be able to place their orders for CUNA cups online, individualize their products and follow the production of their cups live in the SmartFactoryOWL. The fully digitized and transparent production continuously provides data for the AI real lab, which can be used on open platforms for the development of AI applications.

With this infrastructure, the future of the industrial data economy, which the industry 4.0 platform aims to strengthen together with Fraunhofer IOSB-INA within the project BMWi funded AI Living Lab – with open data, simulations and algorithms – will be collaboratively advanced.

PEOPLE BEHIND

people

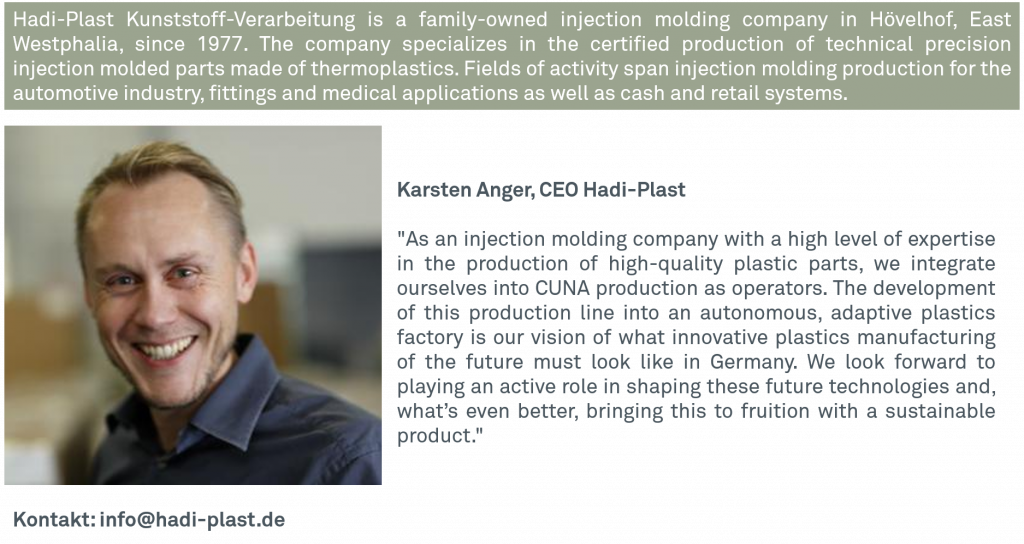

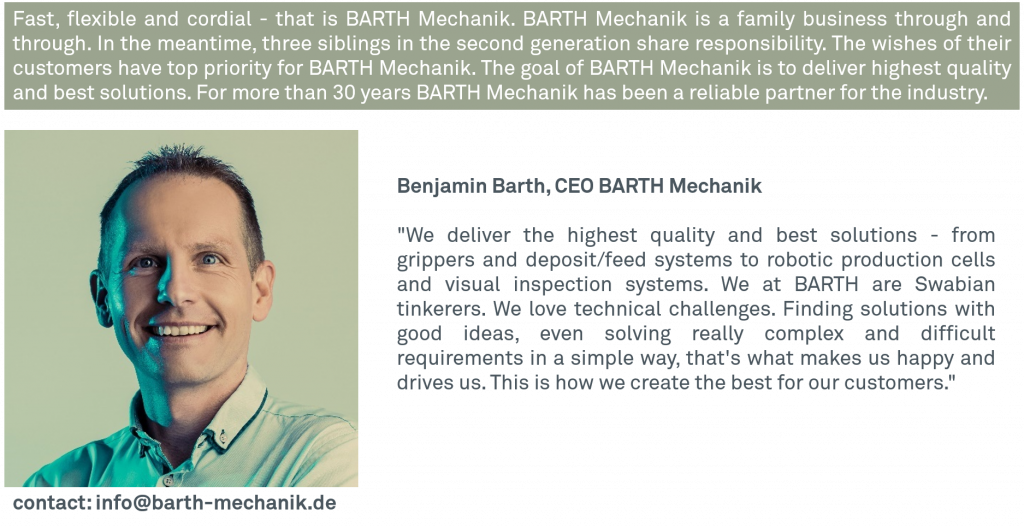

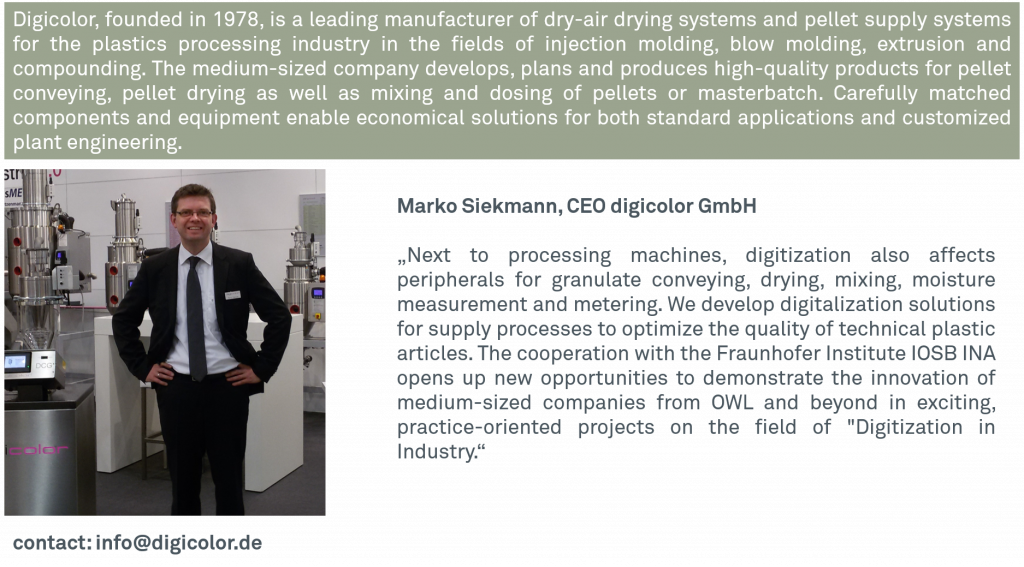

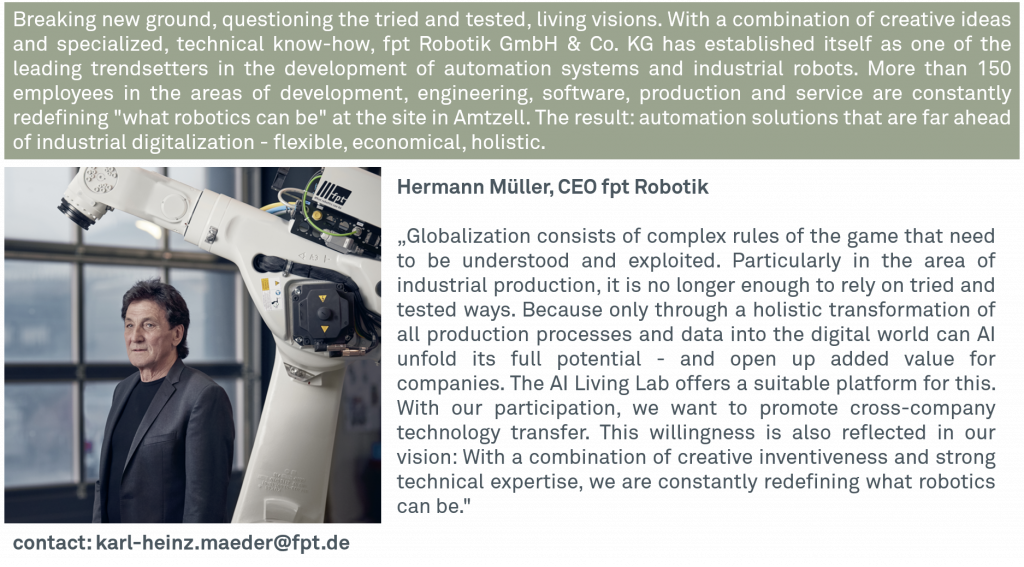

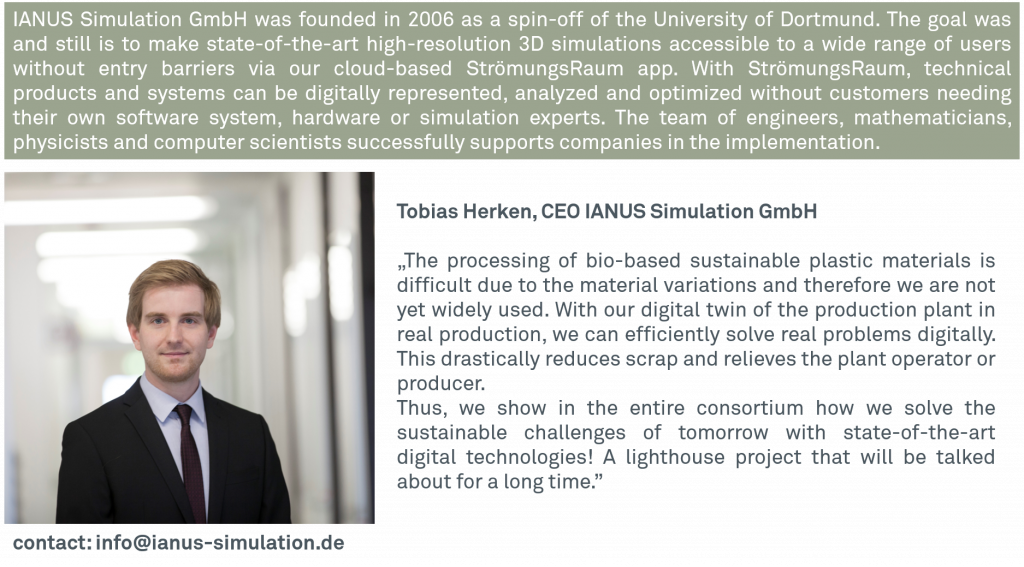

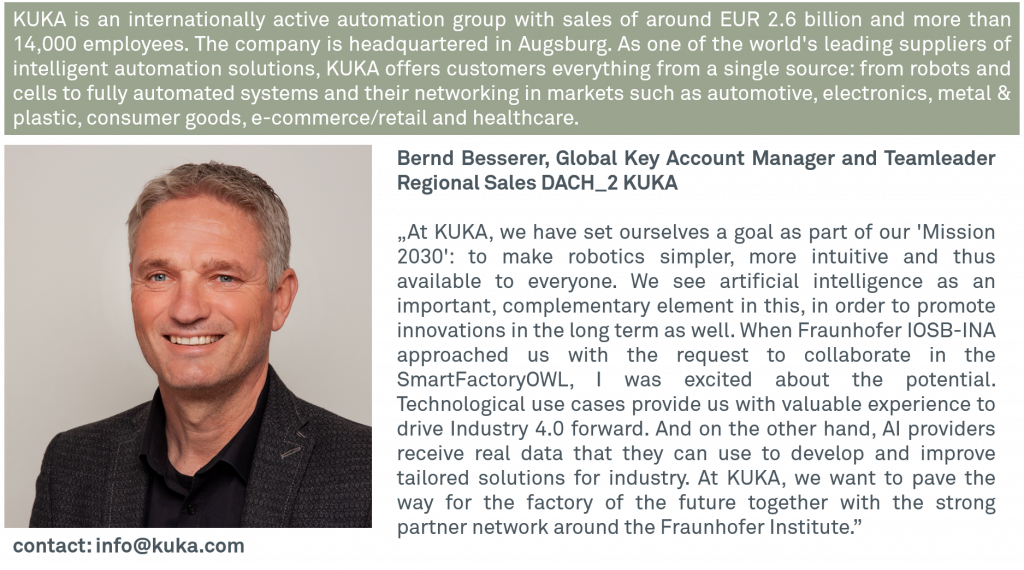

In a cooperative of ten partners, CUNA and Fraunhofer IOSB-INA are setting up the innovative manufacturing. They are supported by the following corporate partners.

The medium-sized plastics manufacturing company Hadi-Plast GmbH & Co. KG is responsible for the production management and operation of the production in the SmartFactoryOWL and contributes expertise from many years of injection molding production. The overall design and integration of the system technology is being handled by the renowned German machine manufacturer ARBURG from Lossburg, which is flanked by other industrial partners such as the globally active robotics manufacturer KUKA and the automation specialists fpt Robotik and Barth Mechanik GmbH. A laser system from REA Elektronik GmbH is used for the individualized labeling of the CUNA cups. The material supply is organized by the Herford-based medium-sized company digicolor GmbH, which manufactures, among other things, granulate dryers and ink systems. The simulation company IANUS Simulation uses available production data to permanently optimize the production processes by means of a visualization of the flows.

In this unique constellation, the manufacture of the sustainable cups with fully networked and AI-supported production is located in the SmartFactoryOWL in Lemgo, in the middle of the OWL technology region and the Innovation Campus Lemgo. It becomes an experimental field for Industry 4.0 and artificial intelligence technologies. Fast and agile technology transfer and integration of jointly developed solutions will be the basis for the cooperation of this future-oriented production in the SmartFactoryOWL.

WHAT WE DO

In several technology projects and use cases, the partners develop new technologies and integrate them into the CUNA real production. Here, research is conducted on the current production and technologies are continuously integrated.

The research pursues the clear strategy of continuously increasing the technological maturity of the production and the product by implementing the use cases. This includes goals such as increasing the modularity and adaptability of production, the transparency of the value chain or the overall sustainability of the product and production. In the following, we present individual selected use cases that are implemented at CUNA real production.

You would like to know more about the story of the CUNA production of you would like to get an insight?

Just contact the office of SmartFactoryOWL