Integrierte Sensorik zur Erfassung von Verschleißerscheinungen

Paderborn/ Lemgo Die Firma Zecher aus Paderborn stellt Druckwalzen und Rasterwalzen unter anderem für den Einsatz in Drucktechnik oder eine Oberflächenveredelung her. Die Rasterwalzen werden in Anlagen eingebaut, die Unternehmen in kontinuierlichen Betrieb nutzen. Hierbei werden chemische Substanzen auf die Walze aufgetragen und überschüssige Farbe an der Oberfläche der Walze abgestreift. Zudem wird die Walze kontinuierlich in hohen Geschwindigkeiten umdreht. Dadurch verschleißt die Walze nach einiger Zeit und Zecher tauscht die Walzen aus.

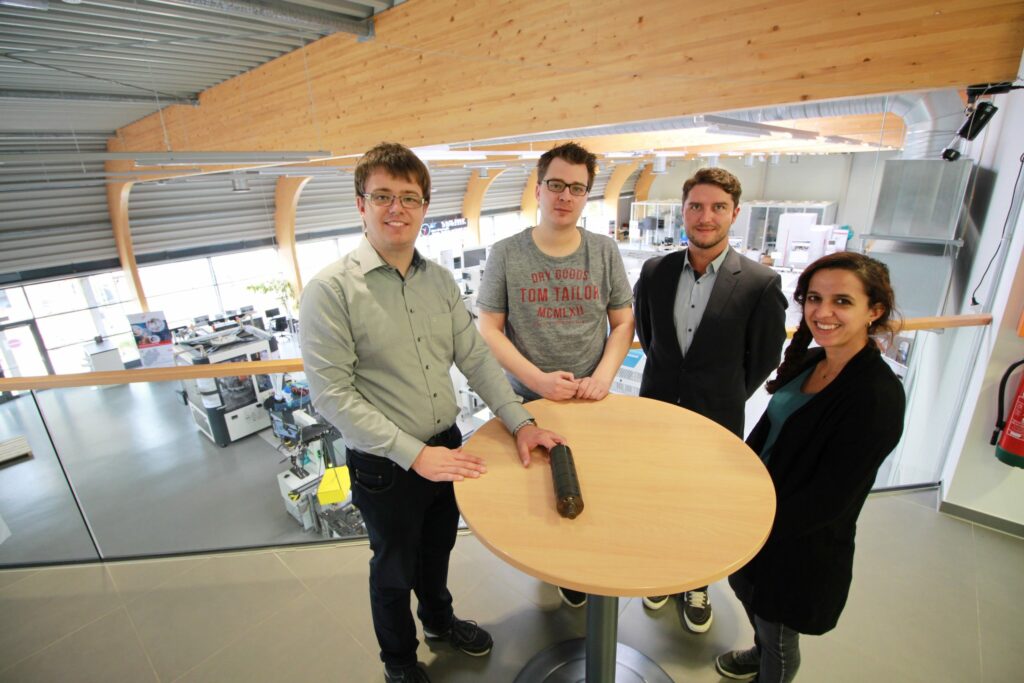

Herr Knauer, CIO bei Zecher ist zufrieden mit dem Projektergebnis und reflektiert: „Digitalisierung ist unumgänglich für die Zukunft des Mittelstands, insbesondere wenn es um neue digitale Geschäftsmodelle geht. Hier sollte man nicht zu lange warten.“

Insbesondere die Kooperation und die Testmöglichkeiten in der SmartFactoryOWL haben ihm gefallen, da sich in Lemgo die Forschung sehr anwendungsorientiert und praxisnah präsentiert habe. Grundsätzlich sieht Knauer noch viel Handlungsbedarf im Mittelstand:

„Wie sollen gerade KMU den internationalen Anschluss schaffen, wenn digitale Themen für sie fremde Themen sind? Technologieaversion kommt bei KMU oft daher, dass das digitale Thema in Deutschland noch wenig angekommen ist. Wenn ich kaum Berührungspunkte im Alltag mit Digitalisierung, wie digitale Bustickets, digitale Taxifahrten habe, kann ich mir auch nur schlecht Anwendungsfälle für mein eigenes Unternehmen vorstellen. Demonstrationszentren wie die SmartFactoryOWL sind deshalb sehr wichtig, um diese Denkansätze und Berührungspunkte herzustellen.“

In weiteren Projekten plant Zecher, gemeinsam mit den Lemgoer Forschern die Übertragung sowie die Energieversorgung der Lösung weiterzuentwickeln. Beide Partner freuen sich auf eine zukünftige Kooperation.

Ob nach zwei oder nach fünf Jahren erste Verschließerscheinungen die Walze unbrauchbar machen, kann Zecher nicht vorhersehen – da wenig Informationen über den Gebrauch in der Anlage vorliegen. Das sollte sich im Rahmen des Transferprojekts bei Digital in NRW ändern.

Gemeinsam mit dem Fraunhofer IOSB-INA erarbeitete Zecher eine Möglichkeit, sensorisch den Zustand der Walze abzufragen. Geschwindigkeiten und Umdrehungen wurden über einen integrierten Sensor erhoben und an eine speziell entwickelte Analysesoftware übermittelt. Die Ergebnisse waren auslesbar, so dass Zecher erste Ansätze für eine Weiterentwicklung und Produkteinführung vorliegen hat.